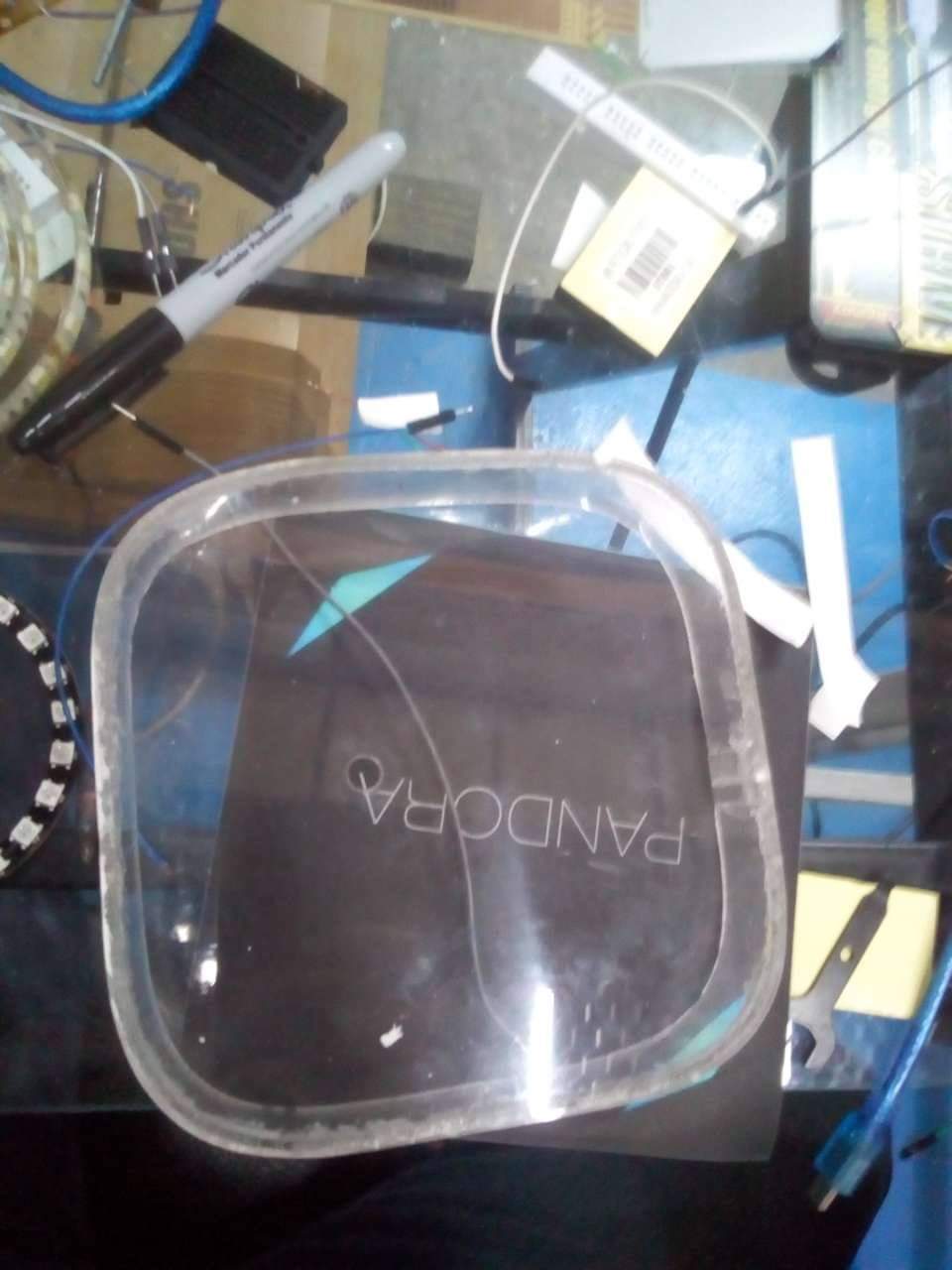

Pandora

Pandora is a hardware and software prototype designed to optimize the assembly process of hydraulic seal kits for heavy machinery. It uses high-precision technologies, computer vision, and connectivity to ensure the quality and accuracy of each assembled kit.

Reworking

Pandora was designed as an innovative prototype that combines both hardware and software to streamline the preparation of hydraulic seal kits for heavy machinery. The system aims to enhance accuracy and efficiency in the packaging process, ensuring that each kit is correctly assembled according to specific requirements. While initially designed for the assembly of seals, Pandora's capabilities can be leveraged in broader packaging processes across various industries.

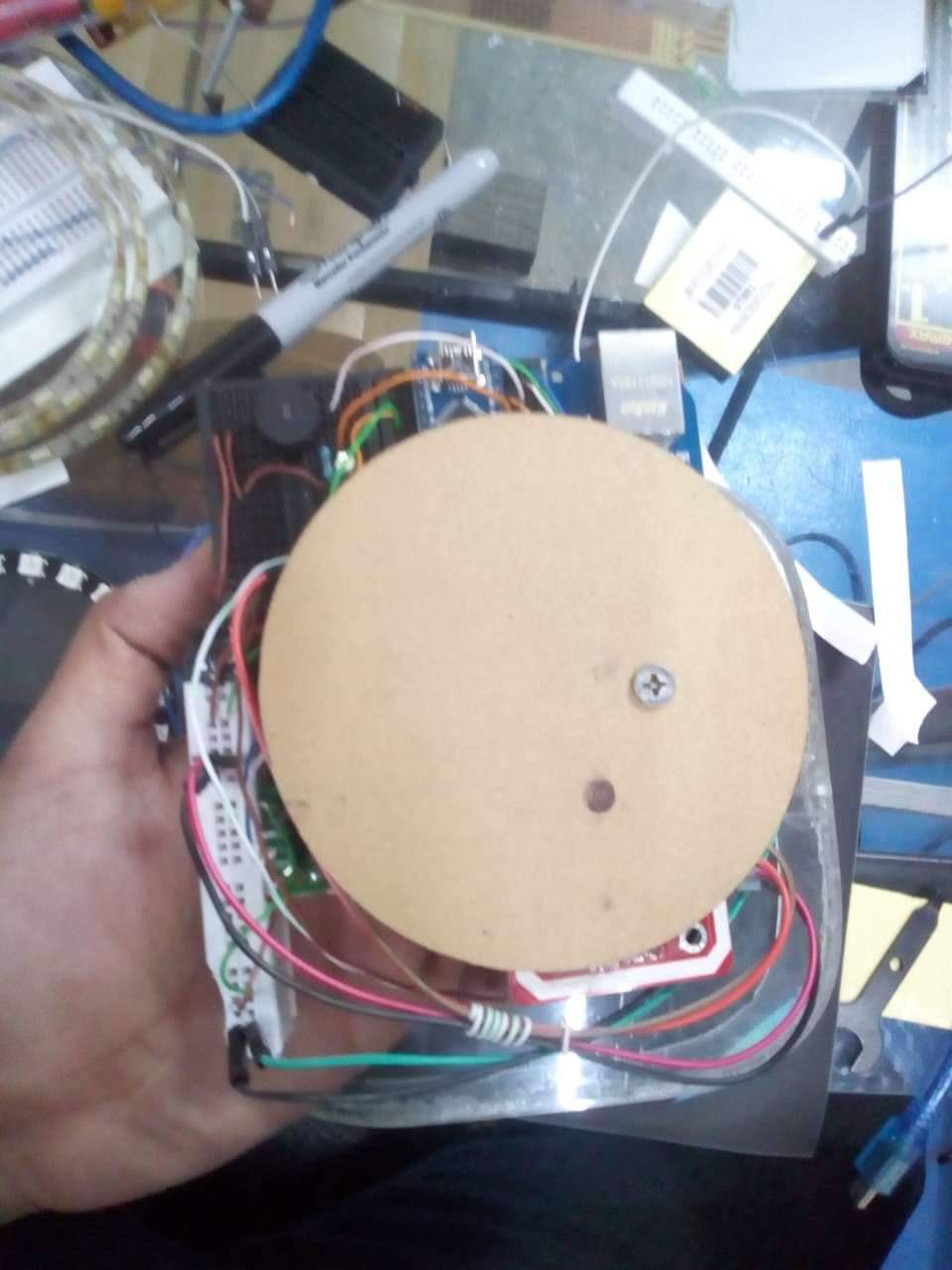

The prototype features a high-precision scale that provides real-time weight measurements, enabling precise verification of each kit's composition. This scale is integrated with a controller equipped with internet connectivity, allowing data to be transmitted to a central status server. The collected data is used to monitor the assembly process, detect discrepancies, and ensure consistent kit preparation.

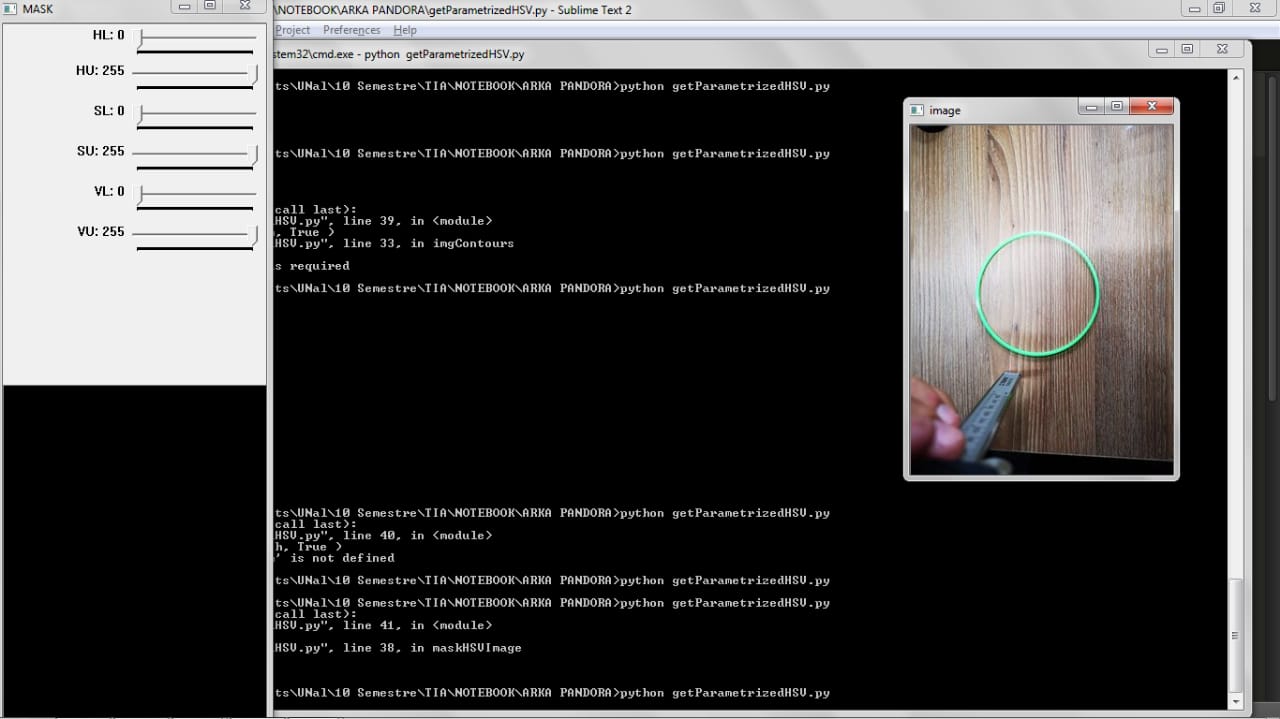

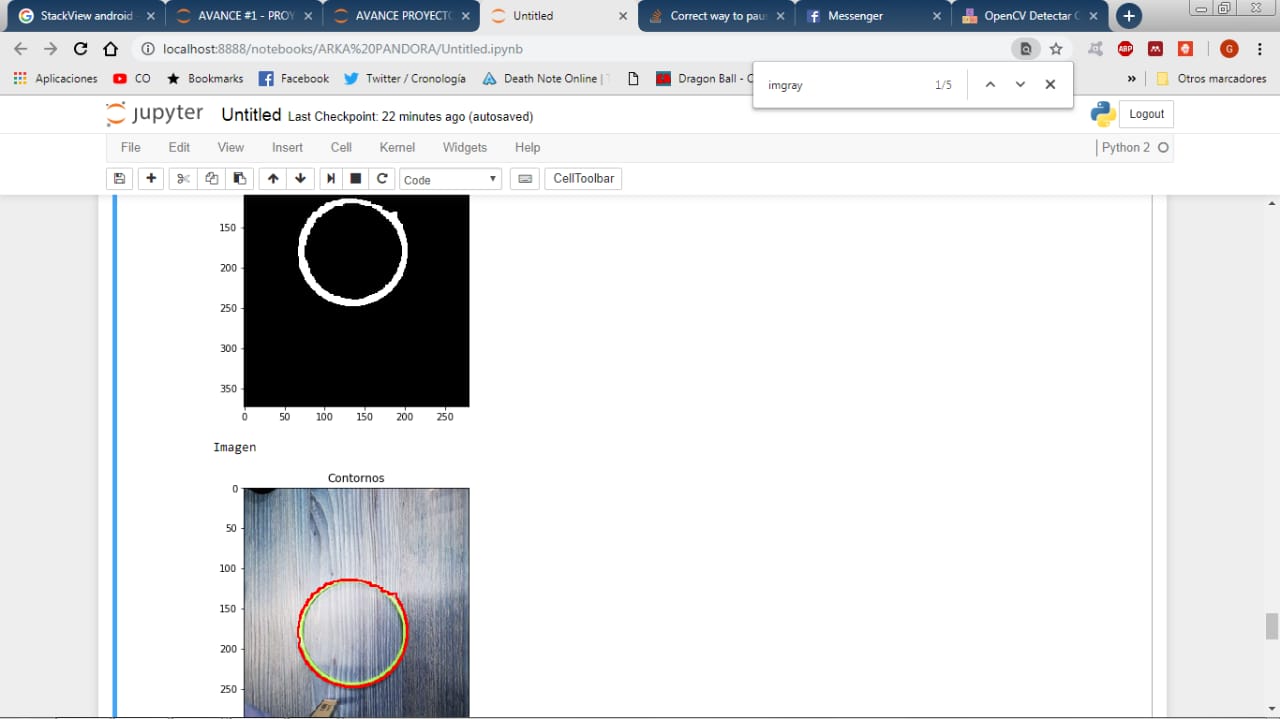

In addition to weight verification, Pandora incorporates a computer vision system to measure the diameters of the seals within the kits. This feature ensures that the correct seals are included and properly configured according to kit requirements. By employing advanced image processing algorithms, the system can accurately identify and validate each component, minimizing errors in the assembly process.

At the end of the packaging process, the fully prepared kit is placed on the scale, which checks whether the total weight matches the expected weight. This step is essential for final quality assurance, as it indicates whether any components are missing or if there are extra pieces. This innovative approach to kit verification reduces manual labor, improves accuracy, and increases overall efficiency in the packaging process.

Pandora's integration of high-precision hardware, intelligent software, and real-time data transmission makes it a groundbreaking solution for the heavy machinery industry. It not only improves the accuracy of kit assembly but also provides valuable insights for process optimization. This prototype demonstrates the potential of integrating IoT and AI technologies into traditional manufacturing processes.